Individual’s attitude and behaviour is crucial for implementing sustainable construction & demolition (C&D) waste management. A recent paper ‘Implementing construction waste management in India: An extended theory of planned behaviour approach’ by Swarna Swetha K et al explores the motivators of workforce towards implementation of construction waste management (CWM) in India.

The construction sector is the major emitter of greenhouse gases (Zhang et al., 2021). Globally 25% of wood, 40% of raw stone, gravel and sand are estimated to be consumed by the construction sector annually (Prakash et al., 2020).

The construction cost shared by material alone is 50%–60% and 9% of the total purchased material end up as waste (Kolaventi et al., 2019). Coupled with the benefits of the urbanization, extensive infrastructure and reconstruction, building projects led to an alarmed rise of construction and demolition (C&D) waste generation in last few years (Jain, 2021).

Construction waste (CW) if not treated pose significant negative effects on the environment which, ultimately leads to severe air pollution with increased concentrations of particulate matter & aerosols. Shortage of landfill sites and non-availability of materials such as aggregates (Kolaventi et al., 2017), create a need for incorporation of reduce, reuse, recycle, recovery in Indian construction sector (Jain, 2021).

Construction waste management has become a major environmental concern in most of the Indian municipalities as the construction waste generated in India is 150 MT and accounts for 35%–40% of the global C & D waste annually (Jain, 2021, Kolaventi et al., 2019).

Centre for Science and Environment estimated that India recycles just 1% of its C&D waste that is being generated (CSE, 2020). Furthermore, it is estimated that, 53 major cities are targeted to setup recycling plants by 2020, of which 13 are established (CSE, 2020). India’s first C&D waste recycling plant is started in 2009 at Burrari.

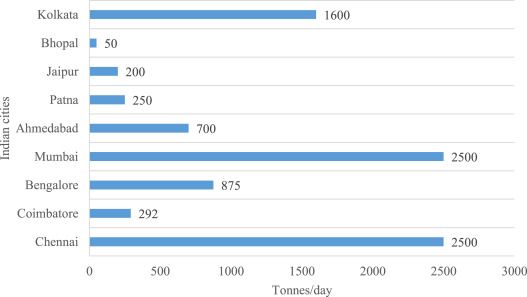

The plant is located in 10 acres plot with a recycling capacity of 2000 Tonnes per day (TPD). Few other operating recycling plants are located at Ranikhera, Shastripark, Gujarat, Andhra Pradesh, Telangana and Madhya Pradesh with recycling capacities of 1100, 550, 300, 200, 500 and 75 TPD. Several other recycling plants are proposed at Ghumanhera, Libaspur, Kapashera, Bakkarwala., Panaji, Coimbatore, Kannur, Mallasandra, Anjanapura, Wagholi, Fathullaguda and Kapuluppada.

It is extremely complex to quantify the C&D waste that is being generated in India (Kolaventi et al., 2017). Currently in India the C&D waste which is being generated onsite is cleared with the help of local vendors. The local vendor, charge a nominal amount to clear the site and in turn trade the material to the individual in need. Thus, the existing scenario, makes the recycling targets, processing and quantification estimations of construction waste tougher.

The study

A hypothetical model using theory of planned behaviour (TPB) is framed fundamentally by incorporating constructs such as knowledge and perceived usefulness. The extended TPB (ETPB) model is then tested via structural equation modelling which utilizes, empirical data from construction workforce in India for the analysis.

The analysis results conclude, perceived behaviour control is consistently crucial construct for predicting behaviour intention in comparison with attitude and subjective norm. Knowledge has significant behavioural impact on implementation of CWM, and the impact of subjective norm and perceived usefulness are insignificant. The study is pertinent to: (i) policy makers — for establishing regulations & practices, (ii) corporates — for devising effective approaches, (iii) academia — for encouraging attitude and behavioural changes towards implementation of CWM.

Conclusion

The existing programmes implemented by the Government of India have a minimal focus on behavioural aspects for implementing CWM. Therefore, the present article attempts to analyse various attitudinal and behavioural factors associated for implementing CWM in India.

The major contribution of the paper is the application of psychological theories — the notion of theory of planned behaviour (ATT, SN and PBC) and institutional theory (KN and PU), to provide a clear picture of associated factors for non-implementation of CWM in Indian construction projects.

As partial mediating factors, perceived usefulness and knowledge explain the complex and evolving decision-making process behind implementation of WM under conflicting environments. Based on which, a theoretical model with seven hypotheses is developed using Ajzen’s TPB and is analysed using SEM.

The analysis results indicate that five out of seven paths have significant influence on implementation of CWM. Perceived behaviour control (0.52), knowledge (0.40) and attitude (0.38) are three significant factors influencing the intention to adopt CWM.

The impact of subjective norm and perceived usefulness is insignificant. This is due to the fact that, in India, social awareness and environmental benefits specific to CWM implementation are limited. The limited awareness results in lower social expectations, minimal or non-existent social norms on CWM. Furthermore, people perceive that costs associated with implementation of CWM are higher in comparison to the benefits.

Based on the results, it is evident that the following conditions may increase the degree of perceived external constraints of a user thereby decreasing the willingness to implement CWM onsite:

- lack of availability of standards on usage of CW products

- increased recycled products price in comparison with conventional materials

- lack of standard documentation

- higher goods service tax (GST) i.e., 18% on recycled products, non-user friendly setup

Based on the above conditions, the following measures can provide better chances for onsite implementation of CWM:

- Providing training on usage of latest techniques such as BIM, GPS, GIS and Big Data, Geo-polymer, Integrated Project Delivery (IPD), Virtual Prototyping, and CAD

- Establishment of contractual clauses which are requisites for implementing CWM,

- Framing of legislations which includes deconstruction plan at planning phase,

- Setting up of recycling target for every project.

- Framing of GST tax waiver policies

- Employment of low budget waste technologies blended with onsite sorting of CW,

- Implementation of SWMP and associated checklists can improve the implementation of CWM at management level.

The full paper can be accessed here